About us

Söderenergi produces district heating for some 300 000 persons, offices and industries in the Stockholm region, and enough electricity to power 100,000 homes. In one year, we convert 1 million tons of waste into energy. Half of that comes by boat to our port in Södertälje. Production takes place at three main facilities; the Igelsta combined power and heating plant, which is Sweden’s second largest biomass-powered combined power and heating plant, the Igelsta heating plant and the Fittja plant. The majority of our heating production is sold and distributed to our owner-municipalities by Telge Nät in Södertälje and Nykvarn and by Södertörns Fjärrvärme in Huddige, Botkyrka and Salem. We also have a production partnership agreement with Stockholm Exergi and Norrenergi. This collaboration increases Söderenergi’s production and sales of heating, and the joint production system is used in a more efficient manner. See our film Söderenergi – Eco-smart energy, English subtitles.

Short facts about Söderenergi

- is the fourth largest district heating producer in Sweden

- produces approximately 2500 GWh of district heating (A normal year)

- produces 500 GWh of electricity (A normal year)

- sells electricity certificates

- produces steam and hot water to the industri in Södertälje

- has Sweden’s first 98-ton wood-chip truck that is powered by 100% biofuel

- has certifications for environmental impact and working environment

- was formed in 1990, see our film Söderenergi the story – being part of the ecocycle

Our business idea

We create sustainable and innovative solutions together with recycling and energy clients in the circular society.

Our vision

A sustainable society and improved quality of life for future generations.

Values

Collaboration, Commitment, Honesty, Openness and Respect are the values that guide everything we do at Söderenergi.

Sustainability

Our benefit to the public

We help our customers and owner-municipalities become more sustainable by supplying competitive and secure energy with a minimal impact on the environment and climate. We must be on the cutting edge in terms of our choice of technology and fuel. We must choose recycled and renewable fuels as well as reduce the use of finite natural resources. Our Environmental service means that we help contribute to better resource management and reduce the environmental and climate impacts of the community’s waste, while at the same time we handle our own waste in an efficient and safe manner. Our business must be driven by increased sustainability, be able to be verified and also include our customers and suppliers in the process. This is sustainable energy generation at Söderenergi.

Söderenergi takes a holistic perspective to sustainable development, which includes both ecological, social and economic sustainability. This penetrates the entire business, and all of our suppliers that we can influence through our actions.

The goal of Söderenergi is to be on the cutting edge in terms of our choice of technology and fuel. We must choose recycled and renewable fuels as well as reduce the use of finite natural resources. The Environmental service that Söderenergi provides means that we help contribute to better resource management and reduce the environmental and climate impacts of the community’s waste, while at the same time we handle our own waste in an efficient and safe manner.

As an employer, neighbour and local business, we partner with and support organisations that share our values and our view of a sustainable society.

To meet today’s needs without jeopardising the opportunities for future generations is what sustainable development means to us.

Our sustainability policy is based on three areas

- Ecology – Climate and environment: Söderenergi enables circular flows within the waste and energy system.

- Social – Work environment: The most important resource is everyone working at Söderenergi.

- Economy – Business ethics: Söderenergi requires transparency, trust and respect.

Our Environmental service, a business model for district heating

Our use of district heating is already a part of the waste management staircase model. We are reducing the need for landfills in Europe. Once the recyclers have sorted sorted out the material that can be recycled and put to use in the community, we take care of the rest. We make energy from the waste by efficiently using resources in a way that is smart for the environment. Emissions into the air and water are clean. Substances that are hazardous to the environment and human health can be stopped from circulating further in the community. Ash and residual products are handled safely and concentrated for future recycling.

We provide an Environmental service that provides local, regional and global benefits for manufacturers, recycling companies, property owners and district heating companies.

Business ethics

Söderenergi strives to achieve good business ethics, long-term and trusting relationships and purchasing in accordance with the principle of public access. We expect you as a supplier to respect the code of conduct and that you assume responsibility for achieving the requirements within your organisation and in your supply chain.

Our plants

When Söderenergi was formed, there were already several plants. A few of these are still used today for reserve power for extremely cold days. Over the years, the plants at Igelsta have been upgraded and expanded in order to be able to provide a modern district heating system. The Igelsta combined heating and power plant was built in 2009, and is currently Sweden’s second largest bio-powered, heating and power plant.

Igelsta combined heat and power plant

This combined heat and power plant is Södertälje’s, Botkyrka’s and Huddinge’s largest environmental investment ever. An investment that will improve the climate, locally, nationally and globally. Carbon dioxide emissions decreased by approximately 75,000 tons of CO2/year, which corresponds to emissions from 25,000 gasoline powered cars that are driven 15,000 kilometres per year.

There is no doubt that the size of the boiler is huge. For example, the main boiler is 50 m high and its entire weight of 3000 tonnes is suspended from the ceiling in order to be able to expand during temperature variations. The turbine and generator weighs a total of 373 tonnes and is one of the supplier’s largest turbines for electricity production with biofuel. Fuel consumption amounts to over 600,000 tonnes of biofuel each year, which corresponds to ~ 100 tonnes per hour!

All of the benefits that this plant provides are generated by efficiently use the recycled wood waste and the forest residues in order to produce both electricity and district heating. The plant’s incinerator uses a circulating fluidised bed (CFB). The bed consists of fine-grained sand, which when combined with combustion air from below and the fuel, creates a hot sand bed that is 850°C. The combustion creates a very high thermal inertia which vaporises the moisture in the fuel very quickly.

A common conception is that the fuel must be dry, few recycled fuels are refined and therefore contain a high level of moisture. Our technology allows this fuel type to be incinerated and even makes use of the heat energy from the moisture through flue gas condensation. The boiler is therefore on optimal place to combust fuel with a high moisture content.

Electricity production occurs in a steam turbine and generator that converts the steam’s thermal energy and kinetic energy into electricity. The input steam is 540°C and 90 bar, this condition is called superheated steam and means that the steam is approximately 240°C warmer than the vaporising temperature. The turbine rotor weighs over 30 tonnes and makes 50 rotations per second. Therefore, this environment requires precise supervision to ensure optimal operations and efficient use of resources.

The combined heat and power plant produces 210 MW of heat and 85 MW of electricity, and the plant is highly valuable to Söderenergi. The operation time per year is ~6200 hours, and produces approximately 1400 GWh of heat and 550 GWh of electricity.

Igelsta heating plant

The heating plant includes three so called heat only boilers as well as a steam generator for delivering high-quality steam to the local industri. The plant was originally built with three identical boilers for pulverised coal cumbustion. Today, all of the boilers have been converted to combust biofuels and solid recovered fuel.

Boiler 1 is primarily powered by solid recovered fuel (SRF). The boiler was converted in 1997 from pulverised fuel to grate combustion. This means that the combustion air is supplied to the fuel bed from below, while the fuel is fed down from above on a “travelator”. The maximum power is approximately 80 MW, and the boiler is one of Söderenergi’s primary plants. Operating time per year are over 6000 hours, which corresponds to ~430 GWh.

Boiler 2 is powered by the biofuel, tall pitch oil. This is a peak load boiler, which means that it is only in operation during the fall and winter seasons. The maximum boiler effenciency is ~ 95 MW.

Boiler 3 is currently fired largely by recycled wood waste (RWW). The boiler uses a bubbling fluidised bed (BFB). The bed consists of fine-grained sand, which when supplied with combustion air from below and the fuel, creates a hot sand bed that is 850°C. The combustion creates a very high thermal inertia which vaporises the moisture very quickly. The boiler is therefore on optimal place to combust fuel with a high moisture content in order to deal with the heat content in the moisture, the boiler is equipped with flue gas condensation. The maximum boiler effenciency is ~ 95 MW, and is one of Söderenergi’s base load boilers. Operating time per year are ~ 3500 hours, which corresponds to 300 GWh.

Fittja plant

The Fittja plant is located in Botkyrka. It includes two heat only boilers with a total output of 380 MW of heat. The plant is fired primarily using wood pellets that are ground into powder. The plant is are generally in operation during winter time.

Our fellow subsidiary, Södertörn’s Fjärrvärme has their headquarters at the Fittja plant.

Skogås heating plant

The facility is located within Huddinge municipality. The district heating system is hydraulically interconnected with Stockholm Exergi’s. The customer demand in this area is about 120 GWh (heat) a normal year, and Skogås provides with 20 GWh. The heating plant has four smaller boilers, fuels are biooil.

In addition to our production plants, we also have our port and our fuel terminal.

Igelsta port

Roughly half of the total volume of solid fuel comes by the sea, primarily from northern Europe. We have room for 2 ships at a time and welcome 150-200 vessels each year. The port includes a small unloading area, a sampling station, a fuel processing station and a conveyor belt. From a safety perspective, the laws regarding marine vessel safety and port safety apply.

Nykvarn’s train terminal

The train terminal is located in an area that is eight hectors large next to the Svealand Railway in Nykvarn. Here, we receive forest residues in containers that come from different parts of Sweden.

The facility also function as a solid fuel depot, and is our central logistical hub. A unique heat-sensing camera system, combined with fire detection and trespass monitoring, is use to monitor each individual fuel pile and analyse temperature trends.

All of the heavy equipment and vehicles on site are run on 100% biofuel, as well as Sweden’s first 74-ton truck for biomass that goes back and forth from the Igelsta plant.

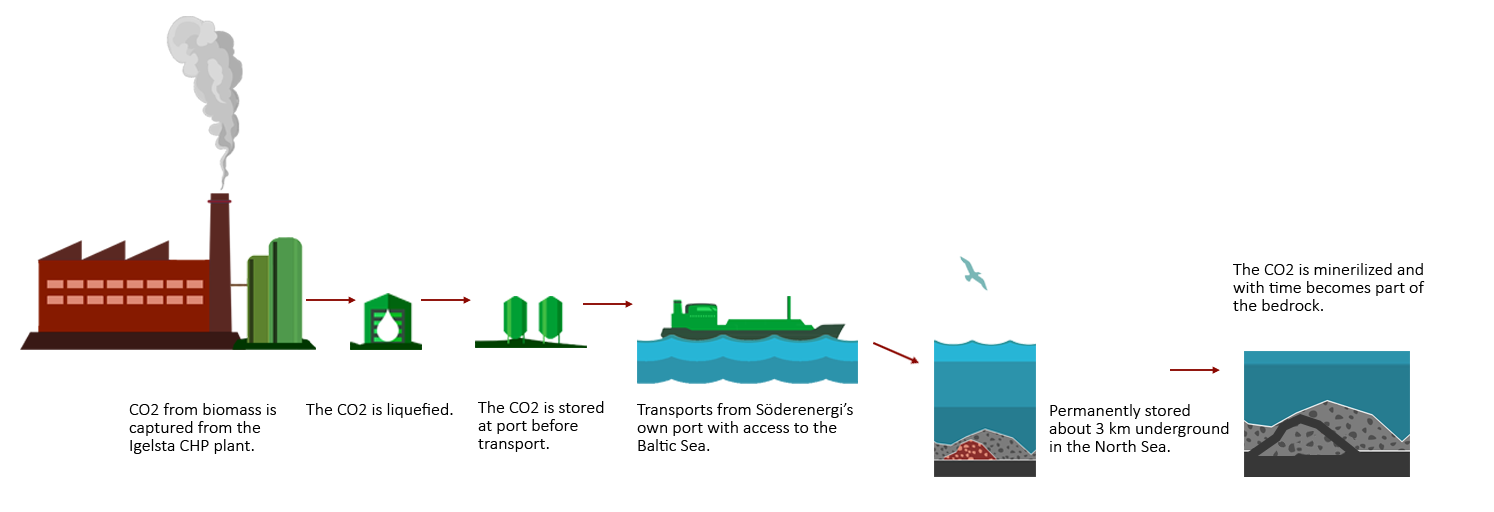

Söderenergi plans for BECCS

Söderenergi can and wants to make a difference. The world needs negative emissions and Söderenergi can contribute to the national and international targets by capture and store 500 000 tonnes of biogenic carbon dioxide per year.

We know that the conditions at the Igelsta Plant in Södertälje are ideal for BECCS (Bioenergy Carbon Capture and Storage). We use biomass fuel in our CHP plant, we have enough space and energy for the process and we have our own port connected to the Baltic Sea, which is an essential advantage.

The BECCS project at Söderenergi started in 2020 and has now reached the fourth phase. The overall goal for this phase is to reach an investment decision and start building a BECCS plant with commissioning in 2030. In addition to this, the logistical chain for the removed carbon dioxide needs to be contracted.

Press release September 10, 2024 – summary in English: Söderenergi recieves 75 million SEK for BECCS project

Project leader Johanna Ek Wahlqvist together with Leif Bodinson, Project owner, tell you more about BECCS at Söderenergi in this video. (English subtitles)

The project is supported by:

How it works

Efficient energy recycling

Söderenergi’s R1-factor is 1.14

The energy recovery efficiency is measured using an energy efficiency factor, R1. The higher the R1 value, the better the energy recovery. The lowest acceptable R1 is 0.65. A value such as 1.14 stands well with waste incineration in Europe, and is due to the fact that we do not just produce electricity but also extract the energy for district heating.

Waste that cannot be reused for new products has its energy recycled in our boilers instead of being buried in the landfill. The energy recovery takes place after recycling and is a natural step in the EU’s waste hierarchy model.

Only waste incineration with efficient energy recovery can be considered proper recycling. This is established in the EU’s framework directive for waste as well as in Swedish waste management regulations.

Fuels

Waste as fuel

When choosing a fuel, we try to balance three important environmental goals: Reduced impact on the climate, Improved resource management and A non-toxic environment. By using waste as fuel, the use of unused renewable and fossil fuels can decrease. According to the EU’s waste staircase model, waste should firstly be prevented from being generated and should be deposited in the landfill as a last resort.

We use primarily recovered and renewable bio fuels.

The benefit of district heating is already apparent in the waste hierarchy model – once the material that can be recirculated and reused has been sorted out, we take care of the remainder and extract the energy from what remains. We do not compete with recycling of waste, rather we use the the waste as a source of energy, which otherwise would be lost, so that we can recover the energy from the waste.

In terms of wood fuel, we demand wood that is produced according to Global Compact’s 10 principles of sustainability, which mean that the fuel must not originate from illegal sources or from protected Forests.

Renewable bio fuel

- Forest residues

- Wood pellets

- Tall pitch oil

Recovered fuel

- Recycled wood waste, RWW

- Solid recovered fuel, SRF

Waste customers

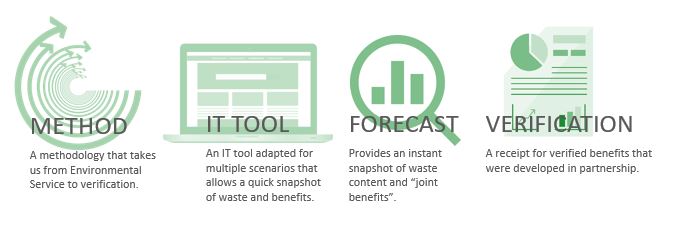

The Environmental Service for our waste customers – as a verification

The climate question and the requirements for circularity are becoming increasingly important, particularly for Söderenergi, which operates in energy recovery. Nowadays, customers demand this as a matter of course.

To show the benefits we bring in our collaboration

Based on our Environmental Service, we have developed a new verification, 2 Mend-IX, that increases transparency and traceability of waste. The verification documents and quantifies the climate and environmental benefits for our waste customers. In specific terms, our tool allows calculation of the benefits arising from a particular amount of waste, including the amount of heat and electricity produced, sorted metal and the amount of heavy metals such as lead.

Contact person: Jan Steinle, Fuel Manager.

Work at site

At Söderenergi, the working environment, safety and environmental considerations always have a high priority. Our work at the plant involves risks, and we take care of your and our safety. People who do not follow our safety and protection guidelines can be immediately dismissed.

For visitors

To visit Söderenergi’s facilities, you need to arrange a specific appointment with a person on site. If you have not passed SSG training, you must be accompanied by an employee when you visit the area or our facilities.

If you will be working inside one of our facilities

Contractors who will be working inside any of Söderenergi’s facilities must have a valid SSG Access card and have completed training in SSG, with passing marks. SSG is responsible for administration and training. Contact Söderenergi’s work environment coordinator if you have questions about using SSG at Söderenergi.

All contractors are required to bring their own helmet and reflective vest.

Site Huts at Igelstaverket

Site huts must be ordered no later than 4 weeks before Your arrival at Igelstaverket.

Ordering and handling staff and office huts

Safety rules for Drivers

At Söderenergi, the work environment, safety and environmental responsibility are in focus. Our work at the facility entails a number of risks and we care about both your and our safety.

Be sure you take part of our security- and safety rules. Upon arrival and to gain access, register with the guard!

- Passengers are not allowed within the premises. Additional driver that comes with training purposes or for long distance transport should be registered with the guard.

- Pets are not allowed outdoors in our premises, only in the vehicle. On your responsibility.

- Respect and comply with traffic rules, signs and instructions on our premises.

- You may only be present in and in the proximity of your vehicle – ensure you have your vest and helmet on before you exit the vehicle!

- Safety goggles and respiratory protection should be used where necessary. Fuel driver should use P3-filter.

- Fall protection is always required at heights in excess of 2 meters.

- Uncover the cargo inside our premises and avoid littering.

- Fuel deliveries who excludes from sampling or scale should be unveiled at the specific area of unloading.

- The remaining fuel deliveries should be unveiled after weighing in (outside scale).

- Do not obstruct other traffic – think before you park.

- Clean the vehicle before you drive out. We care about our immediate environment.

- Cover the cargo space before you leave our premises.

- After delivery, the vehicle should leave our premises as soon as possible.

People who do not comply with our health and safety rules can be immediately removed from the site!

All traffic to and from Igelstaverket should go via Moraberg junction (144) across Gärtuna industrial area

Contact

Hours

Reception

Monday-Thursday: 7.30-16.00. Friday: 7.30-15.00.

Phone: 08-553 055 00

Guard

Monday-Thursday: 6.00-22.00. Friday: 6.00-20.00.

Phone: 076-803 36 90

Location of Igelstaverket

Adresses

Visit:

Igelsta site

Igelstaverket

Nynäsvägen 43

152 57 Södertälje

Fittja plant

Fittjaverket

Sjöbodavägen 5

145 53 Norsborg

Nykvarn´s train terminal

Nykvarns bränsleterminal

Mörbyvägen 22

Mörby industriområde

Nykvarn

Delivery:

Söderenergi

Att: Receivers name

Wedavägen 7c

152 42 Södertälje

+46 8 553 055 00

+46 8 553 055 00